When it comes to automotive maintenance and repair, having the right tools is essential for safety and efficiency. An engine stand plays a crucial role in this process, providing stability and support for the engine during repairs. If you're looking to understand what an engine stand is, how it works, and why it's important, this comprehensive guide will provide all the answers you need.

Engine stands are not just simple tools; they are precision-engineered equipment designed to handle the weight and balance of engines safely. Whether you're a professional mechanic or a DIY enthusiast, knowing how to use an engine stand properly can significantly enhance your work experience.

In this article, we will delve into the world of engine stands, exploring their types, benefits, and maintenance tips. By the end of this guide, you'll have a thorough understanding of why engine stands are indispensable in automotive workshops.

Read also:Rachel Lamb Brown The Inspiring Journey Of A Rising Star

Table of Contents

- What is an Engine Stand?

- Types of Engine Stands

- Benefits of Using an Engine Stand

- How to Use an Engine Stand

- Safety Tips for Using Engine Stands

- Maintenance Tips for Engine Stands

- Choosing the Right Engine Stand

- Common Questions About Engine Stands

- Cost of Engine Stands

- Conclusion

What is an Engine Stand?

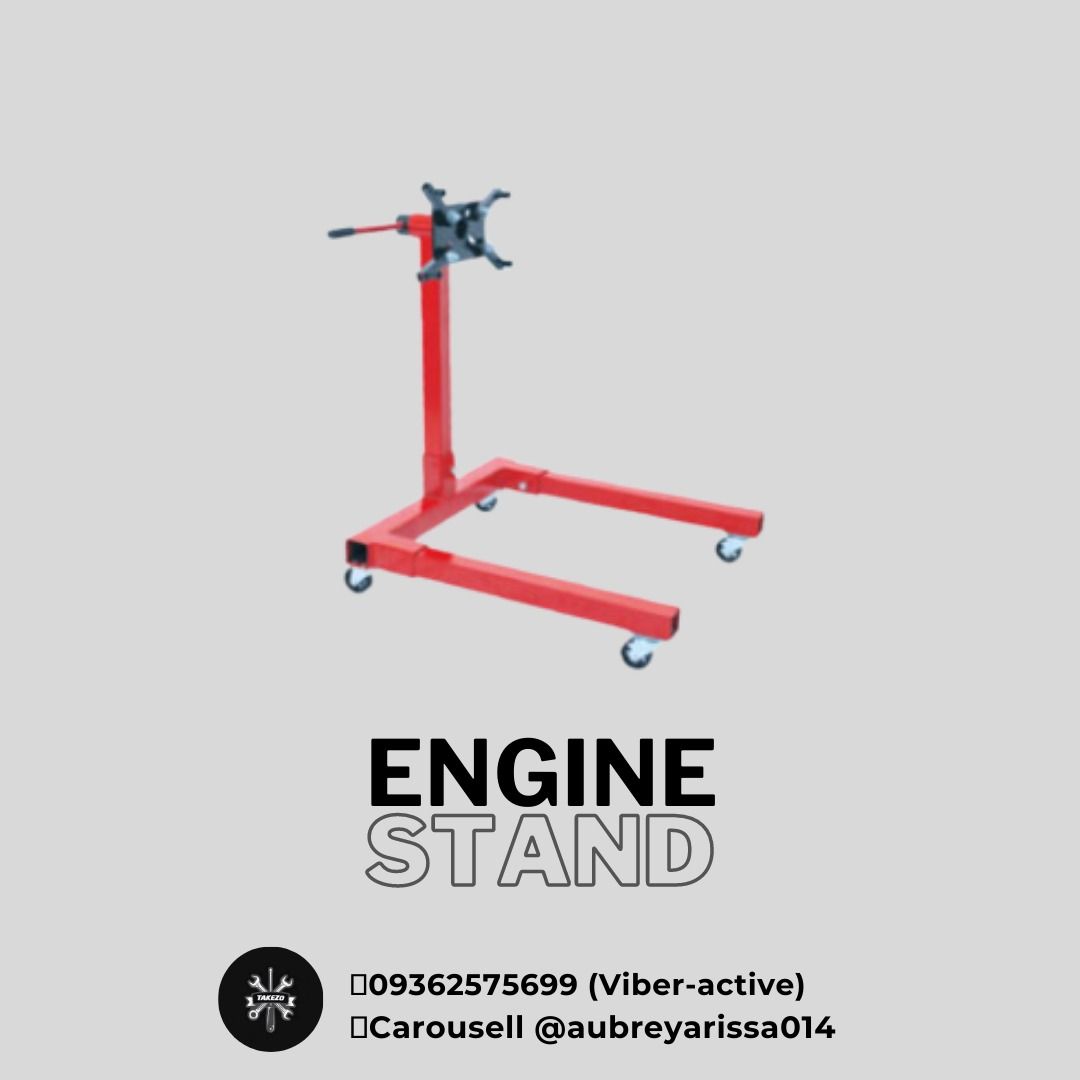

An engine stand is a specialized piece of equipment used to support an engine during repairs, maintenance, or transportation. It is designed to bear the weight of the engine while keeping it stable and secure, allowing mechanics to work efficiently without worrying about the engine tipping over.

Modern engine stands are built with adjustable features, enabling users to position the engine at different angles for easier access. This versatility makes them indispensable in both professional workshops and home garages.

Key components of an engine stand include the base, uprights, and cradles. These components work together to ensure the engine remains secure throughout the repair process.

Types of Engine Stands

Portable Engine Stands

Portable engine stands are lightweight and easy to move around. They are ideal for DIY enthusiasts who need flexibility in their workspace. Despite their compact size, they are capable of supporting heavy engines securely.

Heavy-Duty Engine Stands

Heavy-duty engine stands are designed for professional workshops where large engines are frequently handled. These stands are built to withstand extreme loads and offer robust support for engines during intensive repairs.

Adjustable Engine Stands

Adjustable engine stands allow users to modify the height and angle of the engine. This feature is particularly useful when working on specific parts of the engine that require precise access.

Read also:Arlene Lee A Rising Star In The Entertainment Industry

Benefits of Using an Engine Stand

Using an engine stand offers numerous advantages, including:

- Improved Safety: Engine stands prevent engines from tipping over, reducing the risk of accidents.

- Enhanced Accessibility: They provide better access to various parts of the engine, making repairs more efficient.

- Increased Efficiency: With a stable engine, mechanics can work faster and with greater precision.

- Protection for the Engine: Engine stands prevent damage to the engine by providing secure support.

How to Use an Engine Stand

Using an engine stand effectively requires careful attention to detail. Follow these steps to ensure proper usage:

- Inspect the engine stand for any damage or wear before use.

- Position the engine stand on a flat, stable surface.

- Secure the engine onto the stand using the appropriate cradles and bolts.

- Adjust the height and angle of the engine stand as needed.

- Double-check all connections to ensure the engine is securely fastened.

Safety Tips for Using Engine Stands

While engine stands are designed for safety, proper usage is crucial to avoid accidents. Here are some safety tips to keep in mind:

- Always read the manufacturer's instructions before using the engine stand.

- Ensure the engine stand is rated for the weight of the engine you are working with.

- Regularly inspect the engine stand for signs of wear or damage.

- Never overload the engine stand beyond its specified capacity.

- Use additional support, such as jack stands, if necessary.

Maintenance Tips for Engine Stands

Regular maintenance of your engine stand ensures its longevity and reliability. Consider the following tips:

- Clean the engine stand after each use to remove dirt and grease.

- Lubricate moving parts to ensure smooth operation.

- Inspect bolts and screws regularly to ensure they are tight and secure.

- Store the engine stand in a dry, protected area to prevent rust and corrosion.

Choosing the Right Engine Stand

Capacity

When selecting an engine stand, consider the weight of the engines you will be working on. Choose a stand with a capacity that exceeds the weight of the heaviest engine you plan to use.

Adjustability

Look for engine stands with adjustable features, such as height and angle settings. This will provide greater flexibility and convenience during repairs.

Material

Engine stands made from high-quality materials, such as steel or aluminum, offer superior strength and durability. Consider the material when making your purchase decision.

Common Questions About Engine Stands

How Much Weight Can an Engine Stand Hold?

Most engine stands are designed to support weights ranging from 1,000 to 3,000 pounds. However, it's essential to check the specific capacity of the stand you choose.

Can an Engine Stand Be Used for Transmission Work?

While engine stands are primarily designed for engine support, some models can also be used for transmission work. Ensure the stand is compatible with the specific application before use.

Are Engine Stands Easy to Assemble?

Most engine stands come with detailed assembly instructions and require minimal tools for setup. With careful attention to detail, assembly should be straightforward.

Cost of Engine Stands

The cost of an engine stand varies depending on factors such as capacity, adjustability, and brand. Basic models for home use can range from $100 to $300, while heavy-duty professional stands may cost upwards of $500. Investing in a quality engine stand ensures long-term reliability and performance.

According to a report by Statista, the global market for automotive tools and equipment is expected to grow steadily over the next decade, driven by increasing demand for precision tools like engine stands.

Conclusion

Engine stands are essential tools for anyone involved in automotive repairs or maintenance. They provide stability, safety, and convenience, making them indispensable in both professional and DIY settings. By understanding the different types of engine stands, their benefits, and proper usage techniques, you can make an informed decision when selecting the right stand for your needs.

We encourage you to share your thoughts and experiences with engine stands in the comments section below. For more informative articles on automotive tools and equipment, explore our website further. Together, let's elevate the standards of automotive care and maintenance!